Electroforming Process

Electroforming is a pretty mysterious process to most people, here's a little overview of the steps involved to make each of the electroformed jewelry pieces. In this example I'm making rings:

1. The process begins with making the ring shanks with raw copper bezel or wire, and using a ring mandrel and jewelry hammer to form the ring bases.

2. After the ring shanks have been formed into circles I select cabochons and raw gemstones from my hoard and adhere them to the ring bands.

3. I hand-sculpt settings for the gemstones using epoxy-clay, which then has to cure overnight.

4. The next step is to paint the ring with conductive paint so that the copper will 'grow' onto the piece. Clothespins come in handy while letting the paint dry on these rings. You can also see some in-progress earring studs here.

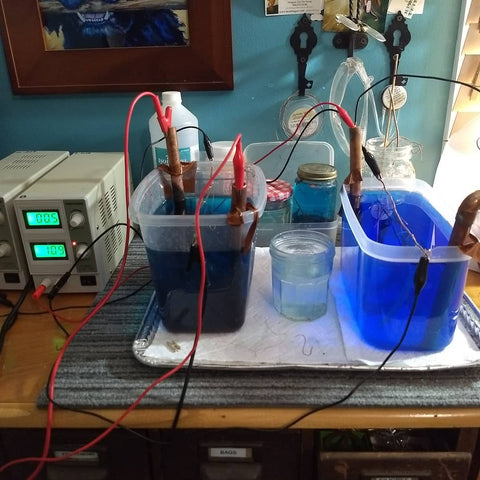

5. Now the piece is ready to go into the copper electroforming bath for 24-48hrs. Here, ions of copper are electrically forced from donor copper pipe onto the conductive surface of the jewelry piece. It takes many hours to build up a thick enough coating of copper, especially for organic pieces like feathers and leaves.

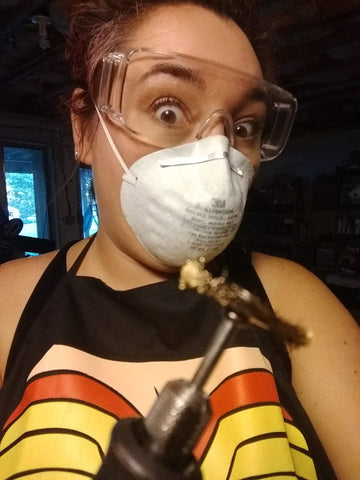

6. Once the pieces come out of the electroforming bath they are neutralized, cleaned, then polished either in a jewelry tumbler, or hand polished with a dremel and wire brush attachment.

7. Next, I hand-patina and re-polish each piece to enhance the texture and give it an antiqued appearance, and the rings are finished!